Augmented Reality Manufacturing Interfaces

visualizing machine data in immersive manufacturing contexts

This work is from my Science Undergraduate Laboratory Internship (SULI) at Oak Ridge National Laboratory, where I worked in the Manufacturing Demonstration Facility in Summer 2023.

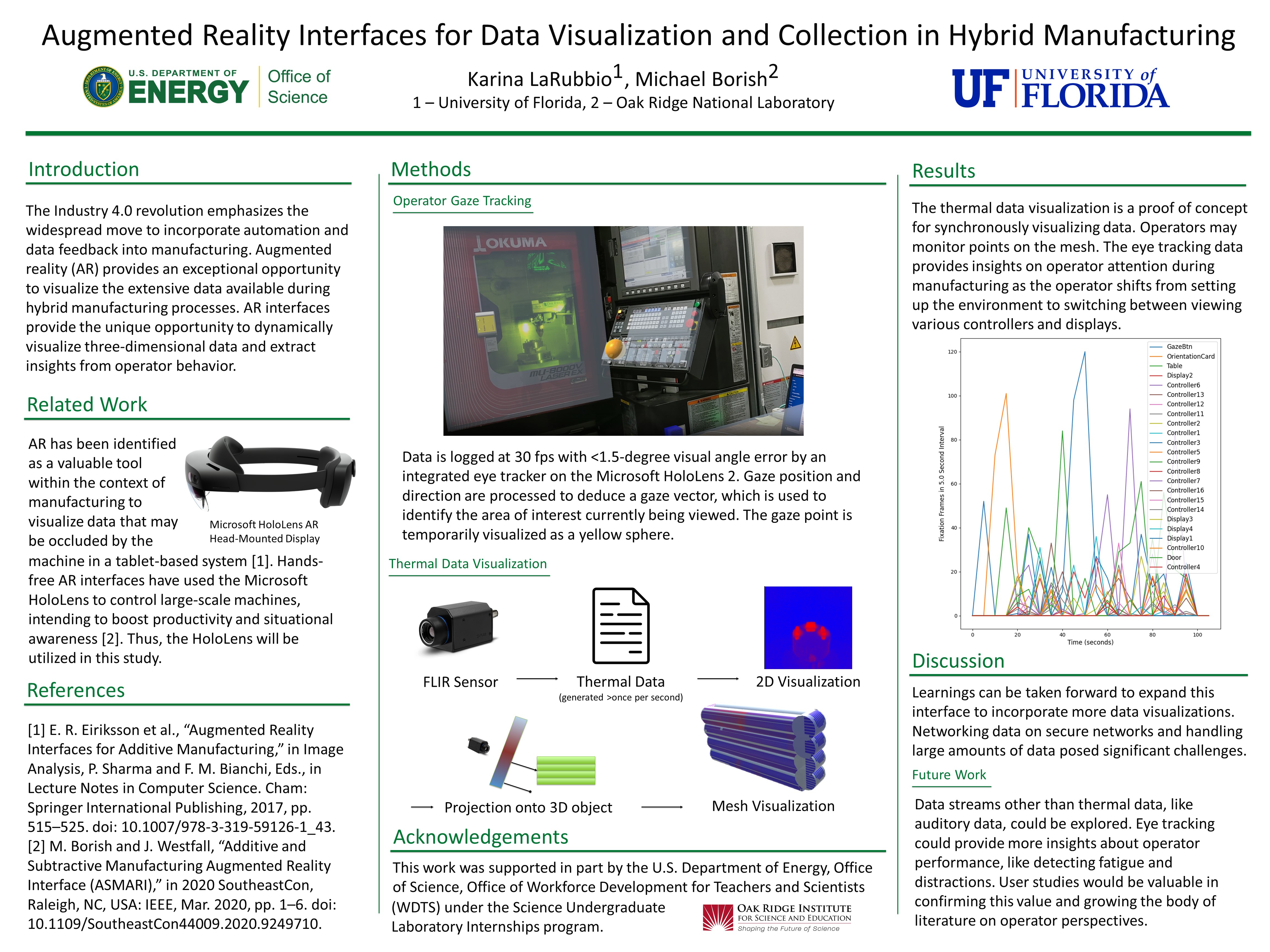

Augmented reality (AR) provides an exceptional opportunity to visualize the extensive data available during hybrid manufacturing processes. A well-designed interface would empower users with data visualizations and insights that could support greater manufacturing efficacy and decrease training time. Along with immediate impacts of AR in manufacturing, insights on operator behavior are uniquely available through sensors that many headsets are natively equipped with, such as gaze, head, and hand tracking. In this study, an AR interface communicates thermal data to operators during manufacturing via a dynamic, interactive, color-coded mesh. Thermal data typically are presented as a two-dimensional image on a screen adjacent to the build cell; this interface projects the data directly onto the three-dimensional object being printed and supports a richer understanding. Additional capabilities collect operator gaze data, which provide insights on operator behavior. Operator feedback will motivate future explorations in AR’s role in enhancing hybrid manufacturing.